Understanding the Whole Process

1-4 weeks

Site Visit

- Understand views

- Understand setbacks

- Plan for install logistics.

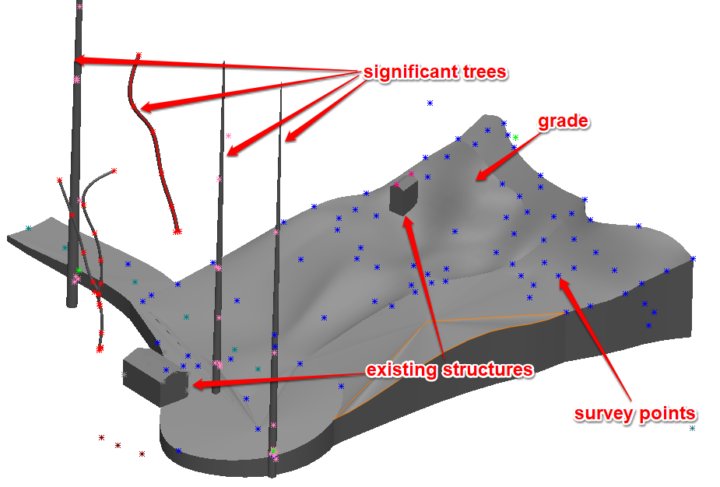

Topography Survey

- Measure local topography with our Leica Total station to make sure house sits effectively with the topography.

Budgeting

- Understand client’s needs and budget

- Review specifications and scope to best meet client’s needs and budget.

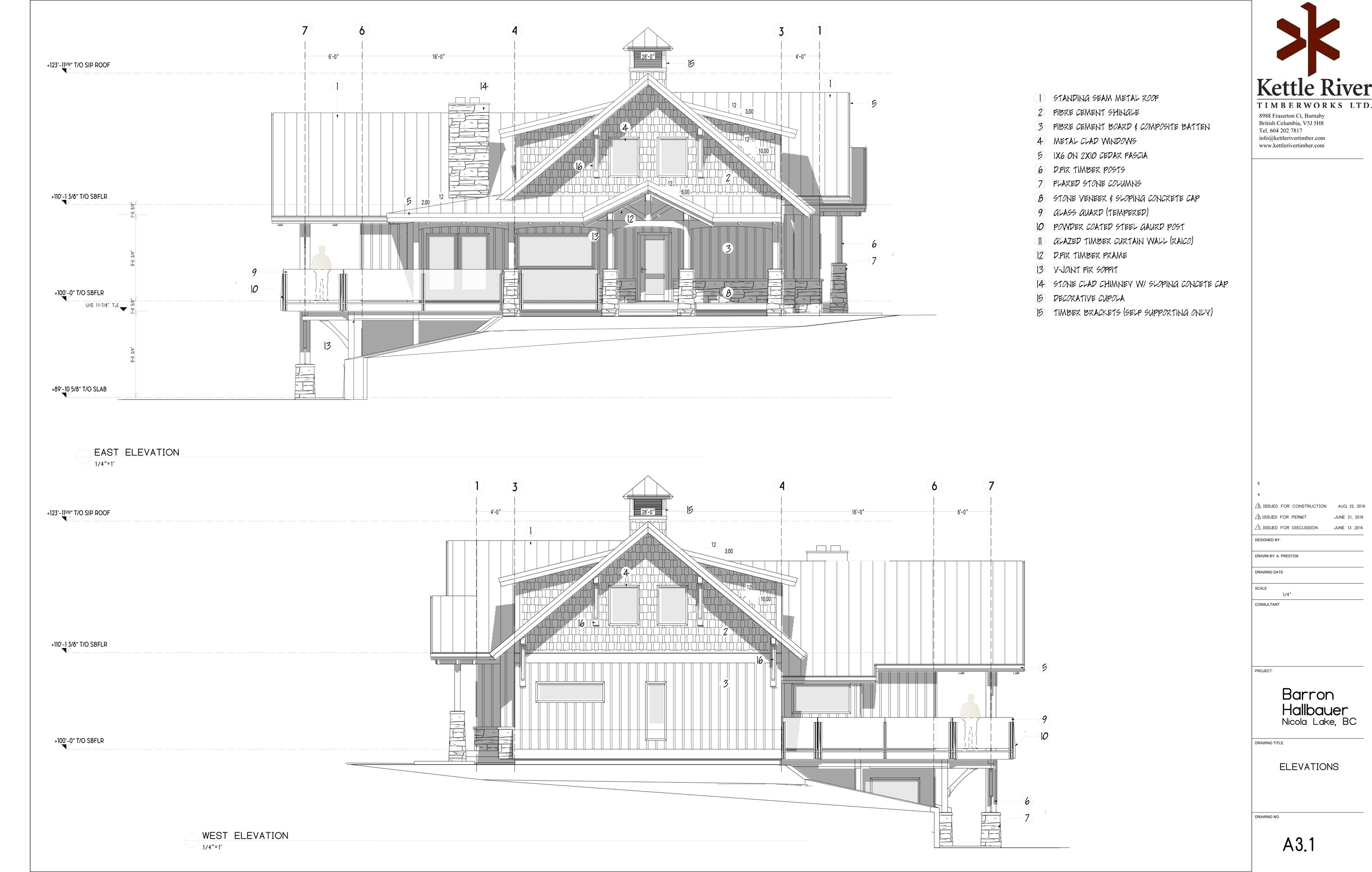

Building Shape (massing)

- Explore rooflines

- Understand general placement and geometry of the home with respect to the topography.

Develop 3D Conceptual Model

Floorplan Development

2-3 months

Timber Frame Design

- Determine timber sizing for structural and aesthetic consideration

- Explore different styles of frames – truss, common rafter, principal rafter.

Design of Specialty Components

- Staircases, mantels, railings etc.

Joinery Design

Timber Cut-List

- Generate optimized timber list and specification for the sawmill.

Structural Engineering

- Finite Element analysis of frame

- Design for wind, seismic, dead and snow loads for pertinent building code.

Roof & Wall Panel Design

- Thermal design of the home to meet or exceed building code requirements

- Develop panel shop drawings.

Stain Selection

- High quality timber stain

- We work with you to help choose a colour you love by providing brushouts to see in person

Development of Timber Shop Drawings

8-14 weeks

Sawmill Timbers

Radio Frequency Dry Timbers

- Required for dimensionally stable timbers.

CNC Cut Timber Joinery

- Multi-axis CNC Machine.

Handcut Specialty Timbers & Log Work

- If required.

Sand & Stain Timbers

Piece Number Timbers

Wrap & Package Timbers

CNC Manufacture SIPS

- cut wire chases

- install engineered lumber

- label panels

Shipping Paperwork

- Bill of ladings

- Border Papers

Load trucks

Develop Raising Plan

- Step by step for erecting timber and panels.

Site Visits

- To ensure good coordination with general contractor as they build foundation and platform

- Use Kettle River Timberworks survey equipment to verify and tweak for site-build conditions if required.

Plan Trucking & Unload Logistics

- Forklift unload

- Crane Unload, usually working with local outfits to minimize travel costs.

2-4 weeks (typically)

Project Coordination

- Kettle River Timberworks project coordinator working closely with general contractors crew.

Raise Structural Insulated Panels

- Nail, tape and seal to meet structural and envelope requirements

Raise & Connect Timbers

- As per structural engineers’ requirements.

Install Ceiling Tongue & Groove (decking)

Install Roof SIPs

Final Inspections

- By Kettle River Timberworks Project Manager & Structural Engineer.

Technical Support for Wiring

- Provide general contractor technical support for wiring of panels.

Installation of High-end Finished Components

- stairs, mantels, etc.

Installation Support

- Support general contractor and client for post-installation maintenance of timbers.

Final Engineering Documents

- Provide final engineering documents – Schedule C-B or Schedule S sealed by Kettle River’s timber engineer.

Photography

- With clients’ permission, photography of finished timberwork and overall project.